is printing using digital technology. Digital printing technology is a high-tech product that integrates machinery, computer, electronic information technology and gradually formed with the continuous development of computer technology.

The emergence and continuous improvement of this technology has brought a new concept to the textile printing and dyeing industry, and its advanced production principles and methods have brought an unprecedented development opportunity for textile printing and dyeing.

Chinese name: Digital printing development history Origin Typical representative of the development status of inkjet printing technology Overview of digital printing all-in-one machine Scope of printing using digital technology Personalized gift market Four advantages of home decoration Fast response and reduced cost.

Due to the impact of the international financial crisis, the field of garment printing processing has been difficult to develop well in recent years, and the number of printing orders will shrink for a period of time. But in the long run, the overall performance will still be relatively optimistic. Corresponding to it is: to adapt to the reality of small batches of printing orders, variety of varieties, rejection of low value-added products, and fast delivery of printing orders as soon as possible, strive for the initiative, and strive to a higher level! Digital printing technology will have a wider application in the field of clothing printing. Digital printing will also go further.

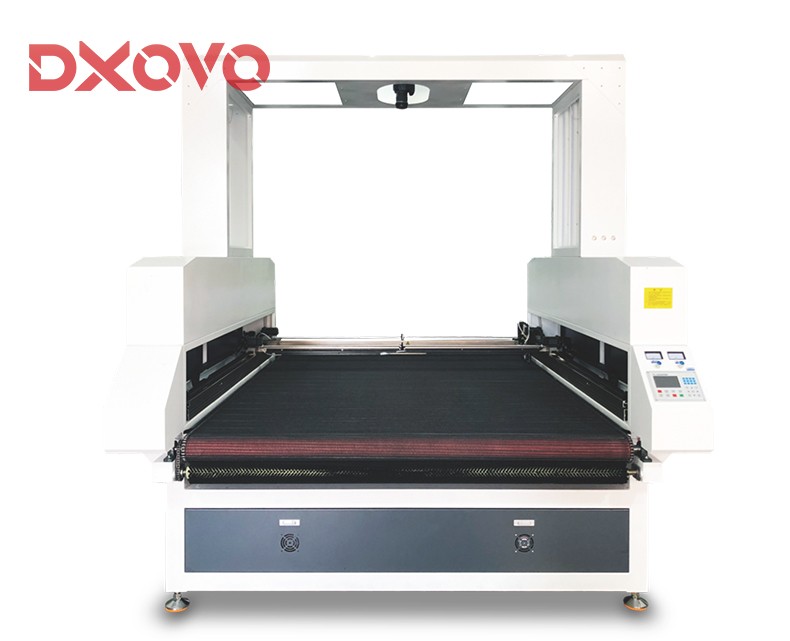

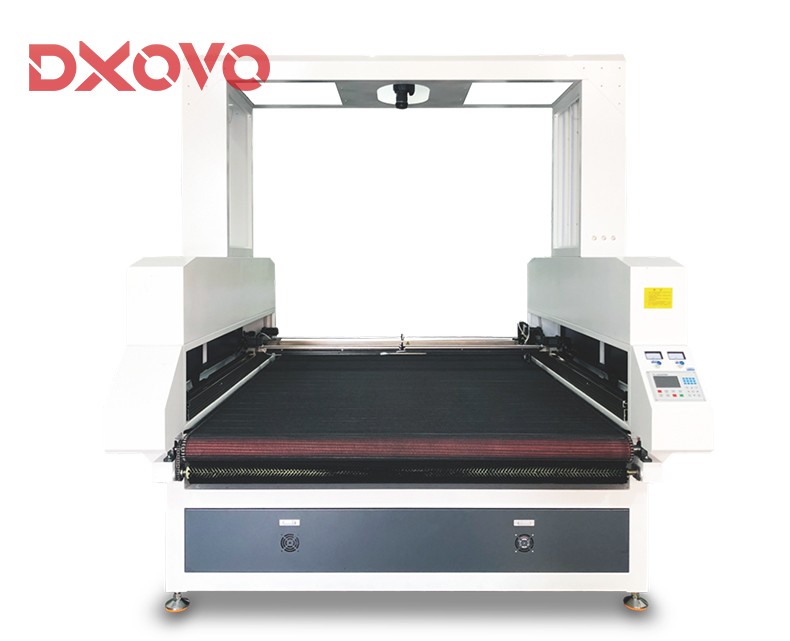

Basic Introduction of Digital Printing

Digital printing works basically the same as inkjet printers, a technology that dates back to 1884. In 1960, inkjet printing technology entered the practical stage. In the 1990s, computer technology began to become popular, and in 1995, an on-demand inkjet digital jet printing machine appeared. The development of digital printing technology is showing a trend of all heroes rising together and a hundred flowers blooming. The technology involved in digital printing is becoming more and more perfect. At present, there are various types of thermal transfer printing, direct injection and so on. In recent years, my country's textile printing and dyeing industry has developed rapidly, and printing output has also increased simultaneously. At the same time, the fashion cycle of clothing is getting shorter and shorter, patterns are changing faster and faster, production requirements are getting higher and higher, order quantities are getting smaller and smaller, and pattern piracy is rampant. Although printing companies have introduced digital methods such as printing CAD systems, laser phototypesetting machines, flat screens, rotary screen inkjet, wax spraying screen machines and other digital means to improve the processing process in the traditional printing methods, the concept of printing and dyeing factories as polluting factories seems to be Has made a deep impression. Later, a Shanghai Textile Technology Co., Ltd. introduced this technology and its advanced production principle and process technology brought an unprecedented development opportunity for textile printing and dyeing. At the same time, the export of my country's printing and dyeing products is increasingly hindered by "non-trade barriers" including the environment. Technically speaking, digital printing is the best way to solve many problems in the printing field. Digital printing is printing using digital technology. Digital printing technology is a high-tech product gradually formed with the continuous development of computer technology. Traditional printing is inseparable from flat screens and rotary screens. However, the cost and time consumed by plate making cannot meet the trend of small batches and multi-variety printing. Therefore, digital printing without plates and pressure is developed. The basic principle is the same as that of inkjet printers and traditional printing regardless of the use of flat screens. This company is a professional company specializing in textile and clothing CAD/CAM/CIMS (computer-aided design/computer-aided manufacturing/computer integrated manufacturing system) application software and its supporting hardware equipment. It is a high-tech company integrating research and design, production and sales, and consulting services. The goal is to transform and upgrade traditional industrial industries with high-tech and advanced and applicable technologies. The main products are to apply CAD, CAM, and CMIS technologies to provide computer software, automatic control machines, and intelligent equipment for the "design and manufacturing" of the textile and garment industry. Design computerization, production automation, control intelligence and management informationization in textile, clothing and light industry. Currently there are product series: garment CAD (pattern making, grading, nesting), garment template, garment cutting and drawing machine, garment plotter, garment inkjet plotter, digitizer, laser machine, digital printing equipment and a series of garments equipment.