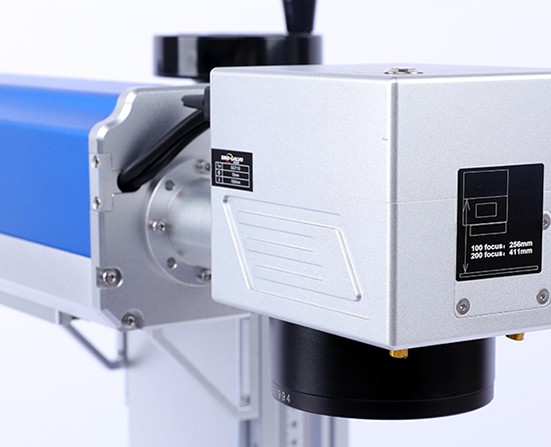

Fiber laser marking machine routine maintenance

Daily maintenance of fiber laser marking machine: the equipment is used for a long time, the dust in the air will be adsorbed on the surface of the lower end of the focusing mirror, the light one will reduce the power of the laser, and affect the marking effect; the severe one will cause the optical lens to absorb heat and overheat and burst When the marking effect is not good, you should carefully check whether the surface of the focusing mirror is polluted

Categorys : FAQ

Sales hotline : +86 13725766389 Lucy Guo

Email : sales@dxovo.com

WhatsApp : +0086 13725766389

Daily maintenance of fiber laser marking machine:

1. When the machine is not working, cut off the power supply of the marking machine and computer.

2. When the machine is not working, cover the lens cover of the field lens to prevent dust from polluting the optical lens.

3. When the machine is working, the circuit is in a high-voltage state. Non-professionals should not overhaul it when it is turned on, so as to avoid electric shock accidents.

4. If there is any failure of the machine, the power supply should be cut off immediately.

5. If the equipment is used for a long time, the dust in the air will be adsorbed on the lower surface of the focusing mirror. If it is light, it will reduce the power of the laser and affect the marking effect; if it is serious, it will cause the optical lens to absorb heat and overheat and burst. When the marking effect is not good, you should carefully check whether the surface of the focusing mirror is polluted.

6. If the surface of the focusing lens is polluted, remove the focusing lens and clean its lower surface.

7. Special care should be taken when removing the focusing lens, and be careful not to damage or drop it; at the same time, do not touch the focusing lens surface with hands or other objects.

8. The cleaning method is to mix absolute ethanol (analytical pure) and ether (analytical pure) in a ratio of 3:1, use a long-fiber cotton swab or lens paper to infiltrate the mixture, and gently scrub the lower surface of the focusing lens. On the one hand, the cotton swab or lens paper must be replaced once.

9. During the working process of the marking machine, do not move the marking machine to avoid damage to the machine.

10. Do not cover or place other items on the marking machine, so as not to affect the cooling effect of the machine.

Daily maintenance of fiber laser marking machine.

Daily maintenance of fiber laser marking machine.

Solutions

Widely used in packaging, advertising, clothing, furniture, bags, footwear, automotive, aerospace, seal, energy, composite, etc.Contact Us

Business negotiation, looking for partners, Join Us.